As an advocate of the 3R movement (Reduce, Reuse and Recycle), Tuntex has always sought to use green manufacturing through continuous innovations. The concept of sustainability in development runs through LuxCushion™.

Reduce

Traditional soft backing systems require a massive water/chemical and energy usage, all of which contribute to a considerable carbon footprint.

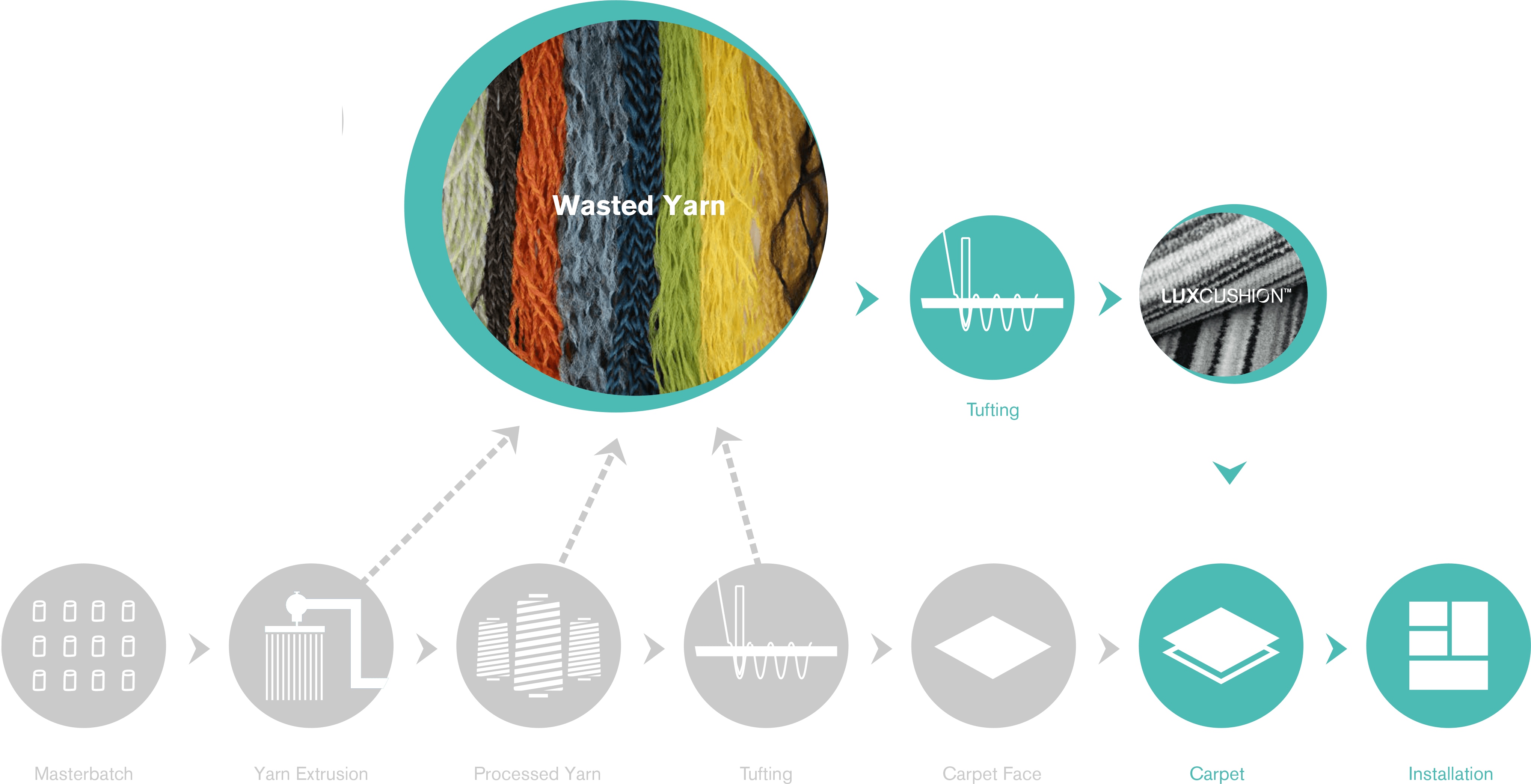

LuxCushion™ repurposes high resilience nylon that is a byproduct from yarn wasted during the carpet manufacturing process and directly uses this yarn into the backing in the original factory. By shortening the manufacturing process and logistics distances, it greatly minimises Tuntex’s overall carbon footprint.

Reuse

From yarn extrusion to carpet manufacturing, every linkage in the production generates wasted yarns. Normally, these wasted yarns will be discarded directly or reproduced through a lengthy process. LuxCushion™ is produced by wasted yarns. We collect and converts these yarns into available materials for the production of LuxCushion™ which maximizes the resource efficiency.

Recycle

Both the face yarn and the backing are recyclable to create the green cycle of carpet production.